welcome to the where your PROJECTS ARE MADE WITH DEDICATION

WHO WE ARE MMF

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

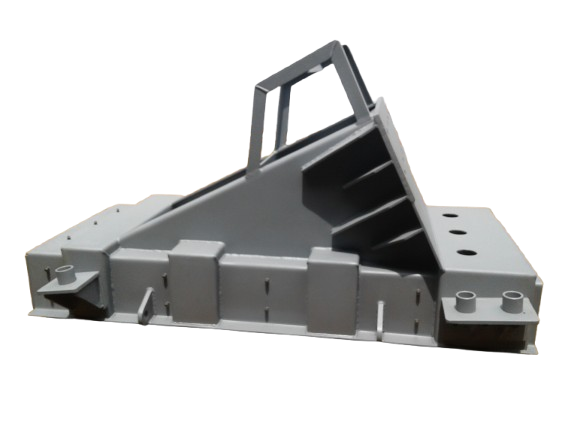

Our Specializations

SERVICES

- Cutting – This is the most commonly used metal fabrication process. Raw materials are cut to spec, using a number of processes, including burning, plasma cuts, saw cuts, waterjet, or laser cuts.

- Bending – Various types of tools are used to bend the metal into its desired shape, whether that be a V-bend, a U-bend, or a custom form required by the project.

- Assembling – Once all the pieces have been formed into their desired shape, assembly can occur. We will fuse the metals together by welding, brazing, and riveting.

- Machining – Because of the uncertainties of the assembly process, a final round of machining may be needed to bring a part back into spec.

- Finishing – After the part is assembled, the surface is treated with coatings, paints, and other custom surface treatments.

Call to enquiries

MM FABRICATION will serve for you any time .

OUR VALUABLE CLIENTS ARE